Bing 54 Carburetor Manual Download

- BING 54 Parts ▼

- BING 54 Jet Charts ▼

- BING 54 Service ▼

- BING 54 Troubleshooting ▼

- BING 54 Advisories ▼

- BING Rotax 912 ▼

Bing carburetors for motorcycles, mopeds, boats, chainsaws, jackhammers and more this web site is specific for motorcycles only if you have an aircraft or another engine with a bing carburetor call us at 800-309-2464 we can assist you. Bing carburetors are stock equipment on all Rotax and HKS engines. We stock all replacement parts and jetting. If you ever have a question concerning the application or the jetting of your carb please call and we'll assist. Useful BMW BING CARB MANUAL. Update date: May 2015. COM have the following tuning a bing carb book available for free PDF download Bing 64 Carb Rebuild Kit, Bing Model 54 Carb Manual, Bing Carb High Idle. AN INTRODUCTORY GUIDE. An individual carburetor veber for toyota 2y manual could BING 64 CARBURETOR MANUAL carburetor adjustments.

Bing 54 carburator needle and clip update Advisory.

Aircraft:

All ultralight aircraft using the Bing 54 carburator used on Rotax and Hirth aircraft engines.

Incident Report: AAIB Bulletin No: 12/98 Ref: EW/G98/07/25 Category: 1.4

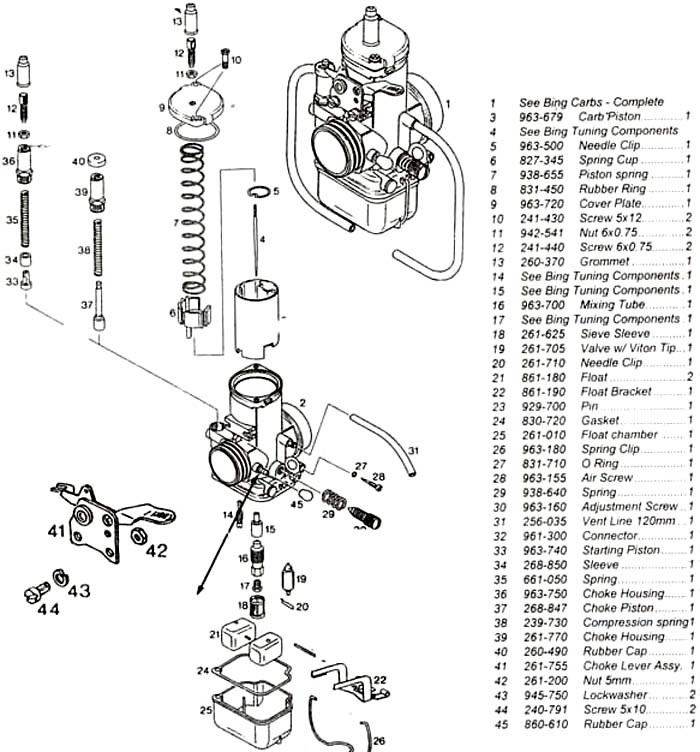

Bing 54 Carb Parts

Aircraft Type and Registration:

Rans S6-ESD XL, G-MZBD

Image on right is just for identification purposes IT is NOT the aircraft involved in this accident report.

No & Type of Engines:

1 Rotax 503 piston engine

Year of Manufacture: 1996

Date & Time (UTC): 19 July 1998 at 1700 hrs

Location: Sittles Field, Nr Lichfield, Staffordshire

Type of Flight: Private

Persons on Board: Crew - 1 - Passengers - 1

Injuries: Crew - None - Passengers - None

Nature of Damage: Significant damage to the landing gear and cockpit floor

Commander's Licence: Private Pilot's Licence

Commander's Age: 42 years

Commander's Flying Experience: 226 hours (of which 25 were on type)

Last 90 days - 32 hours

Last 28 days - 20 hours

Information Source: Aircraft Accident Report Form submitted by the pilot

The pilot reported that during the final leg of a cross-country flight, whilst flying at approximately 1000 feet amsl, the engine RPM decreased from 5,800 to approximately 3,800 and the unit began to run very roughly. Various throttle positions were tried, none of which improved the situation. After some 30 seconds the engine stopped completely, the height by then being 750 feet agl or less.

In view of this low height, no attempt was made to re-start the engine. The pilot judged that the only safe landing field available was directly beneath the aircraft and accordingly he commenced a steep right-hand turn through 360 degrees to position the aircraft into wind and facing up the local slope. Unfortunately, after straightening out the aircraft, insufficient airspeed and height remained to enable the aircraft to round-out into the uphill flight-path necessary for a landing. The aircraft stalled whilst about 10 feet agl.

Examination of the engine subsequently revealed that a needle in the jet of one of the carburettors had detached and fallen into the jet area. It detached as a result of breaking in the plane of the locating groove after severe machining type wear had been inflicted as a result of continuing rotation of the needle relative to its mounting circlip. This problem has been encountered in the past; it occurs under certain conditions of vibration and resonance.

It led to the fatal accident of the similarly powered Colb Twin-Star, G-MWWF, in 1994, see AAIB Bulletin 11/94.

As a result of that accident, the AAIB made the following comments and recommendation to the CAA:-

'The cause of the partial engine failure was that the needle on the rear carburettor had worn through at the circlip and had dropped into the carburettor jet, restricting the flow of fuel to the rear cylinder.

The needle was retained in position by a circlip which was spilt at the apex of the hole holding the needle; the edges of the split had 'machined' away the groove in the needle as it rotated under the forces generated by vibration. This problem is well known and both the UK distributor and the manufacturer (Rotax) have issued safety bulletins calling for a 50 hour inspection of the needle and an ultimate life of 150 hours.

Rotax are developing a modification for new production which will introduce an 'O' ring to each side of the circlip to prevent the needle rotating. The modification is due on the production line at the end of the year. It is therefore recommended that:-

94-35 The CAA require that the modification to the carburettor needle fixture on Rotax engines be made retrospective and mandatory, and that in the meantime the 50 hour check be also made mandatory.'

The CAA did not accept this recommendation. Their reasons were stated in their document 'Follow-Up Action On Occurrence Report ' No F30/94.

The modification ultimately engineered by the manufacturer is slightly different from that described above. It has now been available (at minimal cost) for retrospective installation for approximately 18 months. It is installed on current production engines, although the fact that suppliers and builders of kits frequently store engines for extensive periods results in new aircraft continuing to come into use with engines which may have been built before the modification became part of the production standard.

The aircraft involved in this accident is understood to have completed 49 hours total flying at the time of the accident.

BING 54 jet needle and clip UPDATE

This update prevents wear on the needle and clip. The update requires the purchase of part #831-715 a rubber 0 ring which fits on to the top of the needle, and the installation of a NEW style retaining cup part # 827-347. The new retaining cup has a cut out for the rubber O ring which puts pressure down on the clip and needle to prevent them from turning and wearing.

New style retaining cup part # 827 347

New O ring which can be installed on older style needles part # 950 430

New style clip part # 963 500

This is the new style of clip which can be used with the new rubber 0 ring and retaining cup.

Click here for a quick way to check your needle and clip!

Click here for Rotax update in pdf format

Adjusting the Bing Carburetor

The Bing Carburetor (36mm) is a three stage system:

1.Idle

2.Midrange

3.Top End System.

Idle System

From the moment the engine is started to approximately 1/4 throttle, the carburetor is running according to how the Idle System is set up.

As the idler jet number decreases, the mixture gets leaner; (see part# 4), as the number increases, the mixture gets richer.

Bing Carburetor Parts

For instance, idler Jet #45 has a leaner mixture than idler Jet #50.

ldler Jets

The Air Regulating Screw (see part# 10) must be set as stated in the Bing Jet Chart in order to insure smooth operation of the ldler Jet. This screw adjusts the air/fuel mixture at idle speeds and for smooth acceleration.

Welcome to the user manual for Out of the Park Baseball 17. Out of the Park Baseball is back with OOTP17, the latest version of the best baseball strategy game ever made! New features for this year's game include, among other things: For the first time ever, fully licensed by both the MLBPA and MLB.com! Welcome to the user manual for Out of the Park Baseball 20. Out of the Park Baseball is back with OOTP20, the latest version of the best baseball strategy game ever made! What's New in OOTP20. Pick up and play at any point of the 2019 season with up-to-date MLB rosters, standings, ratings, and injuries! Welcome to the user manual for Out of the Park Baseball 19. Out of the Park Baseball is back with OOTP19, the latest version of the best baseball strategy game ever made! What's New in OOTP19. New 3D Players, Ballparks and Game Screen. Out of the Park Baseball ('OOTP') is the most sophisticated and best-selling baseball simulation game on the planet. Since its inception, OOTP has won numerous awards, including multiple 'Sports Game of the Year' awards, en route to becoming the most immersive, realistic, and customizable baseball experience a fan can ask for! Meaning of users manual.

Turning this screw in a clockwise direction creates a richer mixture while turning it counter clockwise creates a leaner mixture. To adjust this screw, gently turn in a clockwise direction until the screw bottoms out, then loosen the screw (in a counter-clockwise direction) the number of turns as recommended in the Bing Jet Chart. For example, the ROTAX 503A would be .5 (1/2 turn) out (effective range 1/2 to 2-1/2 turns out).

Use the carburetor piston Adjusting Screw (see part# 11) to adjust the idle RPM. Turn this screw in a counter-clockwise direction until the Carburetor Piston (see part# 3) is in the lowest position. Then carefully turn the screw clockwise until it just engages the piston and then continue to turn it clockwise for2 to 2-1/2 full turns. This determines the idle RPM of the engine and should be set at 2,000 RPM.

Midrange System

CANON DISCLAIMS ALL WARRANTIES, EXPRESS OR IMPLIED, INCLUDING, WITHOUT LIMITATION, IMPLIED WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE AND NON-INFRINGEMENT.CANON U.S.A.,Inc. SHALL NOT BE HELD LIABLE FOR ERRORS CONTAINED HEREIN, OR FOR LOST PROFITS, LOST OPPORTUNITIES, CONSEQUENTIAL OR INCIDENTAL DAMAGES INCURRED AS A RESULT OF ACTING ON INFORMATION, OR THE OPERATION OF ANY SOFTWARE, INCLUDED IN THIS SOFTWARE SITE.I have read and understand the information above, and wish to download the designated software. Canon eos ix camera value. Canon 35mm EOS Cameras Limited Warranty Canon International WarrantyThe Limited Warranty set forth below is given by Canon COMPANY listed below with respect to Canon Photographic Products produced in the United States, Canada, Australia, the United Kingdom or New Zealand.The Limited International Warranty is only effective upon presentation of the warranty card and proof of purchase. ALL SUCH PROGRAMS, FILES, DRIVERS AND OTHER MATERIALS ARE SUPPLIED 'AS IS.'

The Midrange System affects the carburetor for approximately 1/4 to 3/4 throttle. Once again, the lower the number of the Needle Jet, the leaner the mixture.

Needle Jets, Jet Needles

(NOTE: Jet needle must always be under plastic spring cup)

The Jet Needle (see part# 2) has three grooves which the Holding Plate (see part# 3) can be snapped onto.

The three grooves are numbered 1. 2, and 3 with number 1 in the top position (note: news jet needles have 4 grooves as in diagram #1 at right).

When the Holding Plate (see part# 3); is snapped onto the top position (#1) of the jet needle, a leaner mixture is created than if it were mounted in the #2 groove.

- lnstall sieve sleeve by slightly squeezing it by pushing it all the way up the mixing tube.

- Smaller numbers indicate decreasing jet opening and leaner conditions.

- The #54 marked on the side of the carb is just a casting mark.

- Float guide pins should be polished to insure smooth float action.

- Floats with aluminum guides should be replaced.

- lnspect jet needle grooves for wear every 50 hours.

- Float arm should start out parallel to the float chamber base.

- Fuel pump must be in system to insure correct fuel level.

How to Check the Float Level

Bing 54 Carburetor Manual Pdf Free

- Start and warm up engine.

- Run the engine at 3/4 power for 2 minutes.

- Let engine idle back and cool down for 1 minute.

- Shut off engine and fuel system (if the fuel system is an overhead system).

- Remove float bowl.

- Remove the floats from the float bowl while float bowl is sitting on a level surface.

- The fuel level should measure approximately 1/2' from the top edge of the floatbowl.

Bing 64 Carburetor Manual

Fuel level below 1/2' will cause a lean mixture.

Fuel level above 1/2' will cause a rich mixture.